Advanced Lab Technology Boosts Sustainability Efforts

in ESG Company News

“At every step of the lab operations, we look for opportunities to be cost-conscious while maintaining high quality — because for our customers, affordability really matters. We want more people to be able to afford the eyewear they need, and efficiency in our lab operations is a big part of how National Vision is able to achieve that,” said Bob McKinzie, National Vision’s Senior Vice President of Manufacturing and Supply Chain. “As socially responsible corporate citizens, we proactively look for opportunities to make decisions that are both low-cost and environmentally aware. Often, these go hand-in-hand.”

National Vision’s optical lab in Plano, Texas, for example, has achieved the lowest operating cost of all labs in our lab network. Despite rising costs for materials and increased wages for workers, the Plano lab has still been able to drive down costs and set a new standard for lab operations. The lab features state-of-the-art technology that has helped drive this success, while also enhancing the work experience for lab associates and increasing efficiency to benefit the environment.

More Efficient Equipment

The Plano lab features some of the most advanced and energy efficient equipment models in the industry. “For some of the equipment in this lab, National Vision is the first — and in some cases the only — optical company in the United States with access to it,” said Bob. “This is because we’ve spent 30 years building great relationships with the best vendors in the optical industry, and because we have the scale to make use of this equipment to truly help many, many people see better. For people in the optical industry, it doesn’t get more fun than this.”

Because of the size of National Vision’s operations, large-scale equipment can be used to perform tasks in larger batches for greater efficiency. For example, according to Schneider Optical Machines, the EBC 1400 AR chambers used in National Vision’s Plano lab — to apply anti-reflective coating to lenses — make use of magnetically levitated turbomolecular pumps to operate at a level that is over 50% more efficient than traditional chambers in the industry. The larger chambers allow more lenses to be coated per batch, thus reducing the per unit of energy output as well as labor.

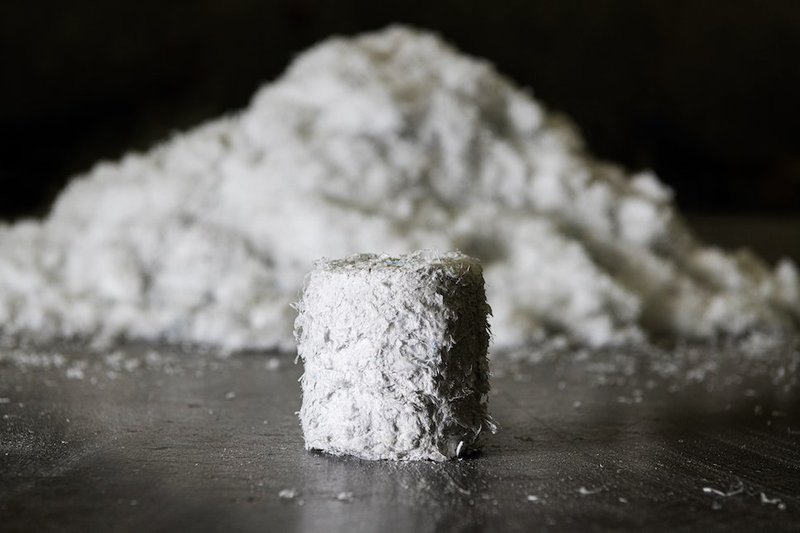

Managing Swarf

When lenses are first purchased from manufacturers, they are about the size and shape of a hockey puck. The material cut off of the lens as it is ground into an individual prescription is called swarf. Managing swarf is a challenge across the optical industry, and it has historically been sent directly to landfills. This is why National Vision is proud to be using machines that condense swarf waste that we cannot recycle.

Briquetter machines, such as the Filtertech LGEN-BR machines used in some National Vision labs, compress swarf into compact blocks that are one-twentieth of the size of the loose material. This results in more efficient waste management with fewer trips to landfills, and the material that we are unable to recycle takes up significantly less space in those landfills. This process also helps National Vision reclaim coolant to be recycled and reused during lens cutting, saving more than 150 gallons of coolant per month across the lab network.

Energy-efficient Lighting

When considering the energy-efficiency of labs, National Vision explores not only increasing the efficiency of the machines used within the lab, but the features of the building itself, including its lighting. National Vision’s labs use energy efficient lighting, including upgrading to LEDs where possible. LEDs are more than 75% more energy efficient than incandescent lighting, and each bulb lasts up to 25 times longer before needing to be replaced.

Health and Safety

Not only do many of the efficiency upgrades in National Vision labs support our sustainability initiatives, they have also led to a safer and more comfortable workplace for our lab teams. Automated technologies help our labs work faster with greater quality controls – while also helping keep our lab associates out of harm’s way and reducing their exposure to moving machinery with potential for injury.

While facilities are designed for optimal energy efficiency, they are also designed with the efficiency of people as well. In addition to ergonomic work-stations, the Plano facility features a large break room with food, gourmet coffee stations, and a game room with bean bags and a ping pong table. “I’m especially proud of our break room,” said James. “It’s another way we go the extra mile to treat our people well and create a safe, productive and enjoyable place to work. All the advancements in our labs have helped us do just that.”

Learn more about National Vision’s commitment to creating affordable, accessible, and environmentally friendly eyewear at nationalvision.com/corporate-responsibility/.